InFORMed - February 2024

A belated Happy New Year and welcome back!

It was another very busy year and, as always, our fantastic team did not disappoint. Their commitment and energy to do a great job always inspires me to stay focused and committed to making Kingsmoor a continued success. I really love what I do and I always feel very fortunate to be leading a business like Kingsmoor Packaging. So, my thanks to all the team for their efforts in 2023 and I’m looking forward to an exciting and busy 2024.

Farewell Tim Priestley

Sadly, I start this newsletter with some very sad news. Last year our wonderful friend and colleague Tim Priestly passed away, after a truly inspiring battle with cancer.

Tim had worked at Kingsmoor for over 30 years and was an amazing man, whose personality and energy made him a fantastic person to know and work with. He was extremely generous and kind and had a wonderfully unique and funny way of embracing life.

Although Tim was a hard worker, he also loved a joke. Whether it was silly hats, signs, or just his sharp wit, he always played an unofficial yet pivotal role in lifting everyone’s spirits and making work fun - a crucial element in manufacturing plastics.

So, it’s with great pleasure that we dedicate this edition of our Informed newsletter to the wonderful Tim Priestley. You will always be alive in our hearts and thoughts.

Christmas Party 2023 - A Tribute to Tim

This year, we chose to honour the memory of Tim at our Christmas party, adopting a theme of silly hats and glasses.

The theme was warmly received by the entire team, reflecting our collective spirit and fond memories of Tim.

Additionally, it was great to witness the team's generous donations to the collection for Wincanton Community Hospital, in gratitude for the compassionate care they provided to Tim during his final days.

Rest in Peace, Tim.

Investments and staff welfare

Our new factory roof and extraction system is now complete and our solar installation is due to be finished by the end of April. The latest investment in on-site renewable energy further strengthens our mission to minimise environmental impact. By harnessing the power of solar energy, we will be able to significantly contribute to the production of our own energy needs.

Our new staff changing facility is on the verge of completion and we are about to start work on the construction of a new canteen, washrooms and offices.

This investment underscores our commitment to sustainability and improving the workplace for our staff.

A new image - Kingmoor undergoes a brand refresh!

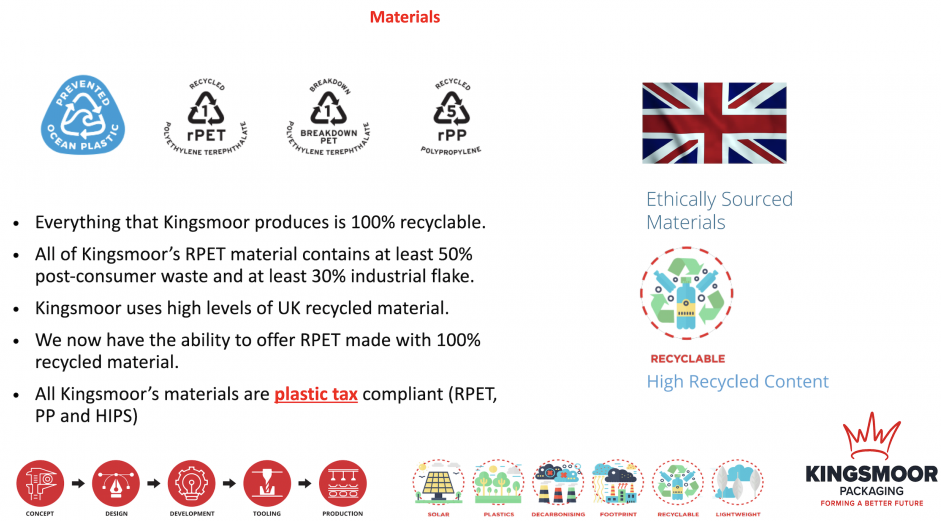

We launched our updated branding in 2023, which is all part of Kingsmoor’s strategy 'Forming a Better Future'. This strategy is Kingsmoor’s commitment to making plastic packagin g as environmentally friendly as we possibly can.

g as environmentally friendly as we possibly can.

Front and centre of our strategy is our focus on:

- Responsible sourcing of our raw materials.

- Using high percentages of recycled content.

- Doing everything we can to aid and support the importance and infrastructure of recycling.

- Creative designs such as our Cirrus brand that helps reduce the amount of plastic required to make a container. In some cases, we have saved up to 30% on pack weight by using our Cirrus design.

Coupled with this, we are also very focused on how we manufacture our products. Using the low-carbon equipment investments that we have recently made, free air chillers, smart compressors and by April this year our on-site renewable solar energy investment will be up and running and will start to power our site and manufacturing facility.

Proud of our heritage

As a leading UK plastic packaging manufacturer, we recognise plastic's crucial role, particularly in the food industry, despite ongoing negative media coverage. Its unmatched durability, lightness and protective qualities make it indispensable. However, plastic deserves better representation and support from the government, retailers and media to help the public appreciate its importance, especially given our demand for diverse, affordable food available year-round.

The ongoing pursuit for carbon reduction in the UK and globally should highlight the challenges with perceived 'greener' alternatives, prompting a closer examination of their origin, production, recyclability, sustainability and potential environmental impacts compared to plastic.

While exploring alternatives is essential for a greener planet, a more strategic approach is needed. Bans and taxes alone won't solve waste issues and could worsen them without enhancing consumer awareness. We advocate a balanced view, like BP's strategy of combining fossil fuels and renewables, plastic and its alternatives must be considered together, focusing on education and informed choices rather than demonising plastic.

Awards

Our new awards day gives everyone the chance to sit down and have something to eat together as a team, and it gives the management team a valuable chance to present and update where we are with everything, have informal chats and get feedback.

We had some food and some live music courtesy of Brad Davies, one of our great toolmakers who loves to sing, in and out of work. Well done everyone!

The Special Recognition Awards were given to the following people for their outstanding work:

- Grace Sharp

- Bradley Davies

- Ben Edwards

- Wesley Finn

- Paul Goodland

- Kathy Elliott

Also, we all commended Andy Harding’s work as he continues to grow in the operations manager's role, where, additionally, he will be overseeing the design, development and tooling departments. Well done Andy!

Movers & Shakers

|

And finally, many congratulations to Chris Musgrave our Tooling Design/Toolroom Supervisor & Procurement Engineer on becoming a Grandad to baby Harry who was born on 3rd December 2023

Congrats Chris!

The Market

RPET and virgin material prices fell dramatically last year up until around autumn when we started to see things level out and increase slightly in the run-up to Christmas. We hadn’t seen last year’s low pricing since the end of the pandemic, which was unsustainable and made good quality RPET hard to find at the right price.

RPET and virgin material prices fell dramatically last year up until around autumn when we started to see things level out and increase slightly in the run-up to Christmas. We hadn’t seen last year’s low pricing since the end of the pandemic, which was unsustainable and made good quality RPET hard to find at the right price.

The demand for PET over the last couple of months has been described by PLATTS as lacklustre, despite coming back after Christmas into a bullish market. Last year’s changes in consumer demands and difficulties in the supply chain with imports, exports, and quality of recycled input, all compounded this lack of demand. Now in the new year and with the crisis in the Red Sea, we are starting to see the effects of upward pricing, despite the low demand.

With the price of paraxylene and PTA rising rapidly, the costs of producing PET in Europe have risen in recent weeks, leaving producers little choice but to pass on costs, which will start to filter up the supply chain over the coming months.

PP softened slightly mid to late summer last year. However, prices started to slowly climb just before Christmas. Demand across the sector is lower than normal and issues with supply in Europe and the Red Sea crisis look like they will start to impact prices over the coming months.

As always, we strive to keep our product quality as high as possible and make sure our customers get what they need when they need it!

Thank you for reading our news!

Back to Insights